With the global electrification drive in full swing, electric cars have constantly been improving in terms of mileage, performance, charging time—and costs. And, Wright's law has so far proven to be right.

According to Wright's Law, aka the learning curve effect, lithium-ion (Li-ion) battery cell costs fall by 28% for every cumulative doubling of units produced. The battery pack is the most expensive part of an electric vehicle, and the sticker prices of EVs have been falling with declining battery costs. By 2023, the cost of Li-ion batteries is expected to fall to around $100/kWh--low enough for EVs to achieve price parity with their gas-powered brethren.

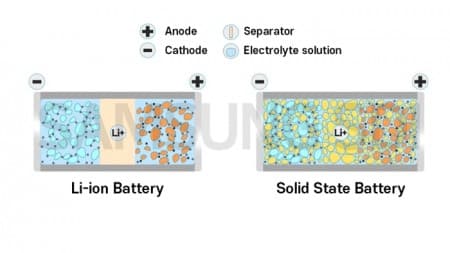

Still, Li-ion batteries come with a suite of disadvantages. Capacity and ability to deliver peak charge deteriorates over time; they bleed a lot of heat and require weighty cooling systems to be integrated into their design, and the batteries can explode or catch fire if damaged in an accident thanks to the flammable liquid they contain.

Over the past few years, EV makers have been touting solid-state batteries as the next breakthrough in EV technology, often quoting insane performance and range. Solid-state batteries use a solid electrolyte that can take the form of ceramics, glass, sulfites or solid polymers as opposed to the liquid or polymer gel one found in conventional lithium-ion batteries.

Solid-state batteries promise some two to ten times the energy density of lithium-ion batteries of the same size, thanks mainly to the solid electrolyte having a smaller footprint. That means more powerful batteries without extra space, or more compact battery packs without compromising on power, longer-range electric cars, and lighter EVs. They are also expected to charge faster.

Better efficiency and energy density also means solid-state batteries don't require the cooling and control components that lithium-ion batteries need.

Finally, solid-state batteries are much safer than their Li-ion brethren due to the solid electrolyte.

Solid-state batteries have been around for a while, but the current crop is mostly non-rechargeable and only used for small electronic devices like RFID tags and pacemakers.

Their biggest drawback is that so far, they have proven to be very costly to manufacture in scale. At the moment, work is ongoing to find the right atomic and chemical composition for a solid electrolyte that has the right ionic conductivity to deliver enough power for an EV motor. Getting the solid electrolyte right is particularly important as it's the precursor to allowing the use of lithium anodes, which can produce more lithium ions and thereby more energy.

Here are five companies in the race to developing the next-gen crop of solid-state batteries.

Source: Samsung SDI

#1. QuantumScape

San Jose, California-based QuantumScape Corporation (NYSE:QS) is a development stage company that engages in the development and commercialization of solid-state lithium-metal batteries for electric vehicles and other applications. The company is backed by Volkswagen (OTCPK:VWAGY), Bill Gates, and SAIC Motors and is regarded as a leader in solid-state batteries.

QuantumScape's solid-state batteries feature a cathode and solid-state ceramic separator that connects to an anode electric contact. When the battery gets charged, the lithium in the cathode gets separated and passes through the ceramic separator that produces a lithium metal anode that generates high energy density charging for electric vehicles. QuantumScape's battery has significant advantages over lithium-ion batteries, including:

Fast charging of 0% to 80% in less than 15 mins compared to 10% to 80% charge in 60 mins for Li-Ion batteries in an EV sedan.

- Lower manufacturing costs due to the elimination of anode host material and manufacturing costs. The company estimates that its batteries will have manufacturing costs 17% lower than Li-Ion.

- Significantly better range due to 80%+ higher energy density relative to Li-Ion batteries. Vehicle range is expected to improve by 50-80%.

- Significantly longer battery life. QuantumScape single layer cells have shown over 1,000 cycles to a median of over 90% energy retention.

QuantumScape expects to deliver prototype samples into commercially relevant form with dozens of layers by 2022 and enter commercial production between 2024 and 2025.

However, with no product in the market yet, QS stock has become a target for short-sellers, who have sent it crashing 70% in the year-to-date.

#2. Solid Power Last month, Solid Power announced plans to go public via a special purpose acquisition company, Decarbonization Plus Acquisition Corporation III (NASDAQ:DCRC) at an enterprise value of $1.2 billion. The company revealed that Ford (NYSE:F) and the BMW Group (OTCPK:BMWYY) aim to utilize Solid Power's low-cost, high-energy battery technology in forthcoming electric vehicles.

Solid Power's balance sheet was significantly bolstered following its $135 million Series B Round (in which Ford and BMW participated), which is in addition to the $165 million PIPE and $350 million from DCRC's cash in trust, and assuming no redemptions by DCRC's public stockholders, Solid Power will receive upon closing, for a total amount raised of approximately $650 million.

Perhaps the single greatest development achievement that Solid Power can boast of is the manufacturability of its cells.

As mentioned before, scalability is one of the greatest challenges for solid-state batteries. Solid Power has adopted Roll-to-roll manufacturing for its own manufacturing process. Since 2019, Solid Power has been operating its pilot plant, a facility capable of an annual output of 6.5 MWh per year. In contrast, QuantumScape does not currently operate a pilot plant of its own, though it plans to open one by 2023.

Related: Colombia Looks Offshore To Revitalize Its Oil Industry

By utilizing roll-to-roll manufacturing, Solid Power has been able to dramatically lower the need for their partners to retool existing production facilities, a costly and time-consuming endeavor. It also lowers the risk of manufacturing equipment used today becoming obsolete within the next decade.

#3. Ilika plc

Ilika plc (OTCPK:ILIKF) is a UK company that engages in the design, development, and production of solid-state batteries primarily in the United Kingdom, Asia, Europe, and North America. It offers batteries for a range of applications in the industrial Internet of Things, electric vehicles, smart cities, consumer electronics, medical, and transportation sectors.

Ilika also accelerates the development of new materials for energy and electronics applications through its patented techniques. The company has developed solid state batteries, super alloys, fuel cells catalysts, a replacement for piezoelectric materials, etc.

#4. Samsung

Last year, smartphone Samsung (OTCPK:SSNLF) unveiled high-performance, long-lasting all-solid-state batteries. The prototype pouch cell that the team developed is capable of powering an EV for up to 800km on a single charge and features a cycle life of over 1,000 charges.

In May, Samsung announced that it will develop large all-solid-state battery cells and prototype all-solid-state battery cells by 2025 and kick off mass production in 2027. Samsung is only second to Toyota (NYSE:TM) when it comes to the number of international patents related to all-solid-state battery technology.

Samsung has been working on all-solid-state batteries since 2008. Last year the company demo'ed an original technique whereby the service life and safety of an all-solid-state battery can be enhanced, and its size halved at the same time.

#5. IBM

Scientists at IBM Corp.'s (NYSE:IBM) Research's Battery Lab have designed a new battery that replaces cobalt and nickel in the cathode while also incorporating a new liquid electrolyte with a high flash point. IBM says this unique configuration is able to limit the creation of lithium dendrites (pesky, needle-like structures that form inside Li-ion batteries and can cause short circuits).

There are manifold benefits to this new battery.

First off, the future supply of heavy metals like nickel and cobalt remains far from certain. Making matters worse, they are also mined in conditions that generally present hazards to the environment, not to mention the child deaths that have resulted from cobalt mining in the Democratic Republic of Congo (DRC).

The cobalt industry has come under fire after several NGOs lobbied the London Metals Exchange to ban trade in tainted cobalt. The majority of the silver-gray metal comes from the DRC, where several organizations have cited human rights abuses especially at artisanal mines.

Second, the high flash point of the electrolyte will drastically reduce the risk of fires or explosions that are quite common even in high-end Li-ion batteries such as those used in Tesla's (NASDAQ:TSLA) EVs.

And last, but by no means least, IBM says the new battery can charge to roughly 80 percent of full capacity in just five minutes; is more energy-efficient and also cheaper to manufacture.

IBM's battery is not the only significant new battery technology to emerge from the realms of techno-wizardry.

The University of Illinois at Chicago has unveiled the world's first fully-rechargeable lithium-carbon dioxide batteries that are seven times more efficient than conventional Li-ion types--fully-rechargeable being the operative phrase here.

The big news: the novel batteries can be recharged up to 500 times.

Another advantage: they are being billed as carbon-neutral batteries that can put a dent in the carbon levels in our atmosphere.

For many years, scientists have salivated at the prospects of a material that could significantly extend the life of Li-ion batteries and allow them to last longer between charges. They discovered that a lithium-carbon dioxide amalgam fits the bill beautifully since it possesses up to 7x higher energy density than common Li-ion batteries. One little problem has been dogging them, though: they just couldn't figure a way to make them last beyond a few charge cycles--that's until now.

Earlier, researchers at MIT demonstrated a prototype that lasted a grand total of 10 charge cycles. The new version by the University of Illinois is, therefore, a big step-up in terms of the charge-cycle grind it can take before giving up the ghost.

The technical cul de sac the researchers have managed to navigate is the tendency of carbon buildup on the catalyst during charging.

According to Amin Salehi-Khojin, associate professor of mechanical and industrial engineering at UIC's College of Engineering and author of the paper, lithium-carbon dioxide batteries have been plagued by the accumulation of carbon which not only blocks the active sites of the catalyst but also prevents efficient diffusion of carbon dioxide and triggers electrolyte decomposition in a charged state.

To get around this challenge, Salehi-Khojin and his colleagues used a hybrid electrolyte in conjunction with molybdenum disulfide as a cathode catalyst to help incorporate carbon in the cycling process. In other words, the scientists created a single multi-component composite product rather than a hodgepodge of separate products, which helped enhance the recycling process.

While the new batteries still cannot hold a candle to high-end Tesla batteries that can be recharged up to 5,000 times and last a million miles, 500 charge cycles is good enough to make them practical for many everyday uses, including in portable power packs, smartphones, UPS systems, and possibly even some EVs.

By Alex Kimani for Oilprice.com

More Top Reads From Oilprice.com:

- Natural Gas Prices Still Have Room To Run

- A Contrarian Investor’s Approach To OPEC’s Oil Spat

- U.S. Shale Can’t Afford To Gamble On The OPEC+ Outcome

Strong buy

"They're why Teslas don't explode whilst simply parked in your driveway" whereas (cough cough) "The General Motors Approach et al"(Kia, Hyundai...same said of Ford better not!) but yes Seeking Alpha Petersen who really is an expert on all things battery really has become quite the silenced.

Hybrids work.

Turbines work.

Hydrogen fuel cell work.